PVDF LINED BUtterfly Valves

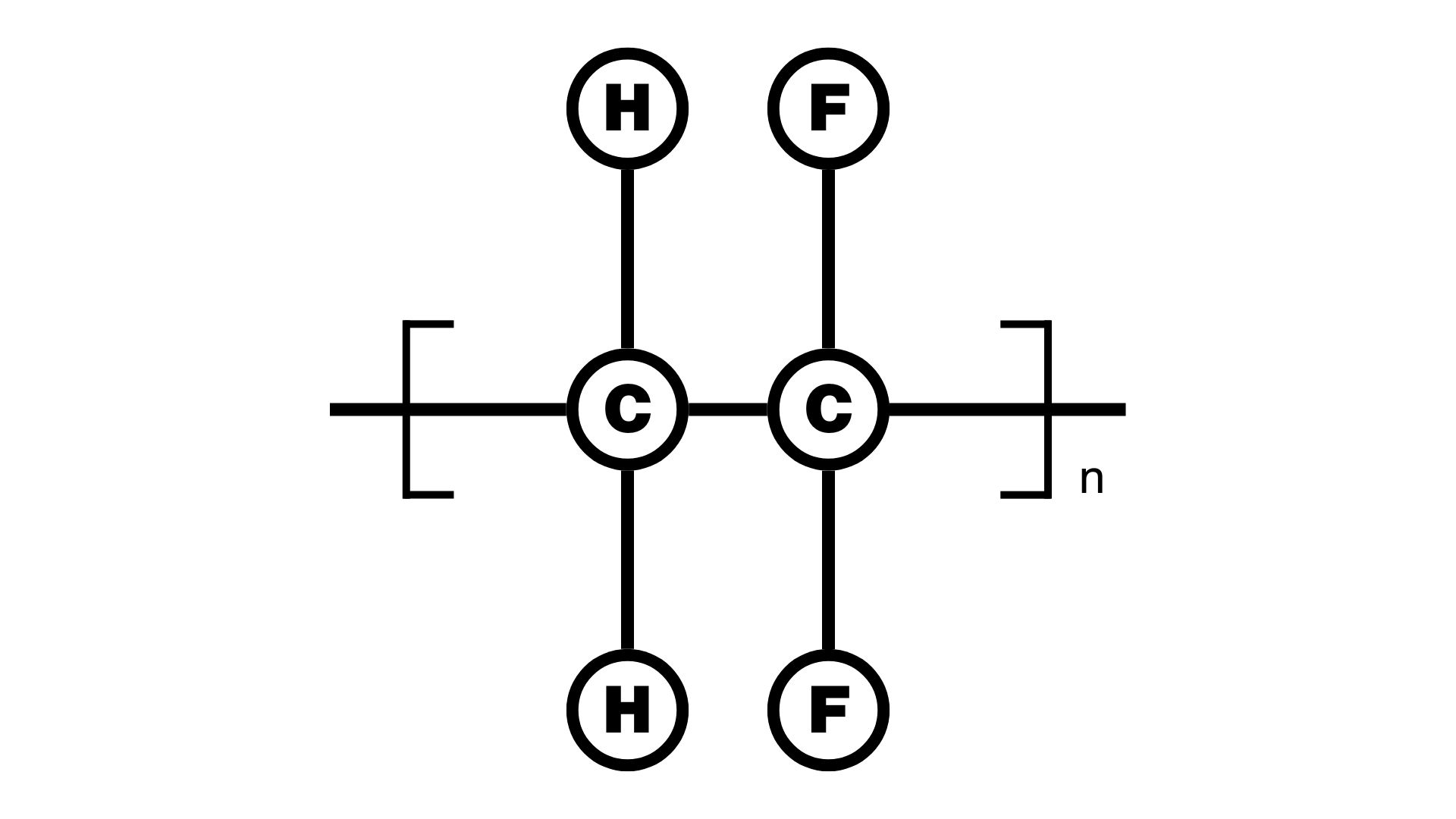

These valves with Polyvinylidene Fluoride (PVDF) lining significantly improves their performance, durability, and application range.

Corrosion Resistance

Smooth Flow Path

Lightweight Design

Cost-Effective Alternative

Versatile Actuation Options

Our Story

Understanding Butterfly Valves and Their Components

Before diving into the advantages of PVDF linings, it’s important to understand the primary components of a butterfly valve:

- Valve Body: The main housing that connects to the pipeline and contains the internal components. It must withstand internal pressures and resist environmental factors.

- Disc: A circular component that rotates within the valve body to open or close the flow passage. The disc is crucial as it comes into direct contact with the fluid.

- Stem (Shaft): Connects the actuator or handle to the disc, transmitting the torque needed to rotate the disc.

- Seat: Provides a sealing surface between the disc and the valve body to prevent leakage when the valve is closed. The seat often incorporates a lining material for enhanced sealing and corrosion resistance.

- Actuator or Handle: The mechanism used to operate the valve, which can be manual (lever or gear-operated) or automated (electric, pneumatic, or hydraulic actuators).

- Lining: A protective layer applied to the internal surfaces of the valve body, disc, and sometimes other components, enhancing resistance to corrosion, abrasion, and chemical attack.

PVDF Material Advantages

PVDF is a high-performance thermoplastic fluoropolymer known for:

- Excellent Chemical Resistance: Withstands a wide range of aggressive chemicals, acids, bases, and solvents.

- High Purity: Low leachable contaminants, ideal for high-purity applications.

- Thermal Stability: Operates effectively across a broad temperature range (-40°C to +140°C).

- Mechanical Strength: Offers durability and resistance to wear and abrasion.

- UV and Weather Resistance: Suitable for outdoor installations without degradation.

Unique Features of PVDF-Lined Butterfly Valves

- Corrosion Resistance: The PVDF lining protects the valve’s internal components from corrosive media, extending the valve’s lifespan.

- Smooth Flow Path: The lining creates a smooth surface, reducing turbulence and pressure drop.

- Lightweight Design: PVDF-lined valves are lighter, simplifying installation and reducing support requirements.

- Cost-Effective Alternative: Offers a balance between performance and cost, providing an economical solution.

- Quick Operation: The quarter-turn action allows for rapid opening and closing requiring swift flow control.

- Versatile Actuation Options: Compatible with manual levers, gearboxes, or automated actuators.

Benefits Specific to PVDF-Lined Butterfly Valves

1. Enhanced Chemical Compatibility

- Broad Resistance: Suitable for acids like hydrochloric acid, alkalis like sodium hydroxide, and organic solvents.

- Process Integrity: Minimizes the risk of chemical reactions between the valve material and the media.

2. Improved Operational Efficiency

- Low Torque Requirements: The smooth PVDF surface reduces friction between the disc and seat, requiring less force to operate.

- Energy Savings: Reduced actuation force leads to lower energy consumption in automated systems.

3. Application Flexibility

- Temperature Resilience: Maintains integrity in processes ranging from cryogenic temperatures to elevated temperatures up to +140°C.

- Pressure Handling: Suitable for a range of pressures commonly encountered in industrial piping systems.

4. Hygienic Design

- Non-Adherent Surface: The PVDF lining resists biofilm formation and scaling, crucial for sanitary applications.

- Easy Cleaning: Supports CIP (Clean-In-Place) and SIP (Sterilization-In-Place) processes.

5. Environmental and Safety Compliance

- Fire Safety: PVDF has flame-retardant properties, contributing to safer operation.

- Regulatory Approvals: Meets standards like FDA compliance for food contact and NSF/ANSI 61 for drinking water systems.

Applications of PVDF-Lined Butterfly Valves

Chemical Industry

- Acid and Alkali Handling: Ideal for transferring aggressive chemicals used in manufacturing processes.

- Chemical Dosing Systems: Precise control in adding chemicals to reactions or treatments.

Water and Wastewater Treatment

- Disinfection Processes: Managing chlorine and other disinfectants.

- Corrosive Effluent Management: Handling treated water with residual chemicals.

Pharmaceutical and Biotechnology

- High-Purity Water Systems: Ensuring contamination-free transport of purified water.

- Process Fluid Control: Managing sensitive fluids in drug manufacturing.

Food and Beverage Industry

- Hygienic Fluid Handling: Suitable for liquids where taste and purity are essential.

- Cleaning Solutions: Withstanding caustic cleaning agents used in sanitation.

Semiconductor Manufacturing

- Ultra-Pure Water Distribution: Preventing contamination in microchip production.

- Chemical Delivery Systems: Safe handling of high-purity chemicals.

Selecting the Right PVDF-Lined Butterfly Valve

Considerations for choosing the appropriate valve include:

- Chemical Compatibility: Match the valve’s materials with the specific chemicals in your process.

- Temperature and Pressure Requirements: Ensure the valve can handle your operating conditions.

- Actuation Method: Decide between manual (lever or gearbox) and automated (electric or pneumatic) operation based on control needs.

- Seal Material: Select compatible seal materials (e.g., EPDM, FKM) that offer the necessary chemical resistance.

- Size and Connection Type: Choose the correct valve size and connection type (wafer, lug, or flanged) for your piping system.

Installation and Maintenance Tips

- Proper Alignment: Ensure the valve is correctly aligned during installation to prevent undue stress on the stem and disc.

- Torque Specifications: Follow manufacturer torque recommendations for flange bolts to avoid deforming the valve body or compromising the lining.

- Regular Inspections: Check for signs of wear, corrosion, or damage, particularly in harsh operating conditions.

- Clean-In-Place Compatibility: Utilize the valve’s ability to be cleaned without disassembly if your process requires it.