PLASTIC LINED VALVES

Types of Plastic Linings for Industrial Valves

Cost-Effective, Corrosion-Resistant, and Abrasion-Resistant

Polytetrafluoroethylene (PTFE)

Known as Teflon, PTFE is highly resistant to chemicals, temperature extremes, and wear.

Perfluoroalkoxy Alkane (PFA)

PFA offers similar chemical resistance to PTFE but with improved mechanical stability and higher resistance to stress cracking.

Ethylene Tetrafluoroethylene (ETFE)

ETFE has exceptional chemical and impact resistance and can tolerate higher temperatures than many other plastics.

Polyvinylidene Fluoride (PVDF)

Known for high purity, strength, and UV resistance, PVDF is used for valves in environments requiring both chemical resistance and exposure to outdoor conditions.

Polypropylene (PP)

PP linings offer excellent chemical resistance to acids and alkalis but are limited to lower-temperature applications.

Polyethylene (PE)

High-density polyethylene (HDPE) linings provide good abrasion resistance and flexibility, making them ideal for applications involving slurry or abrasive media.

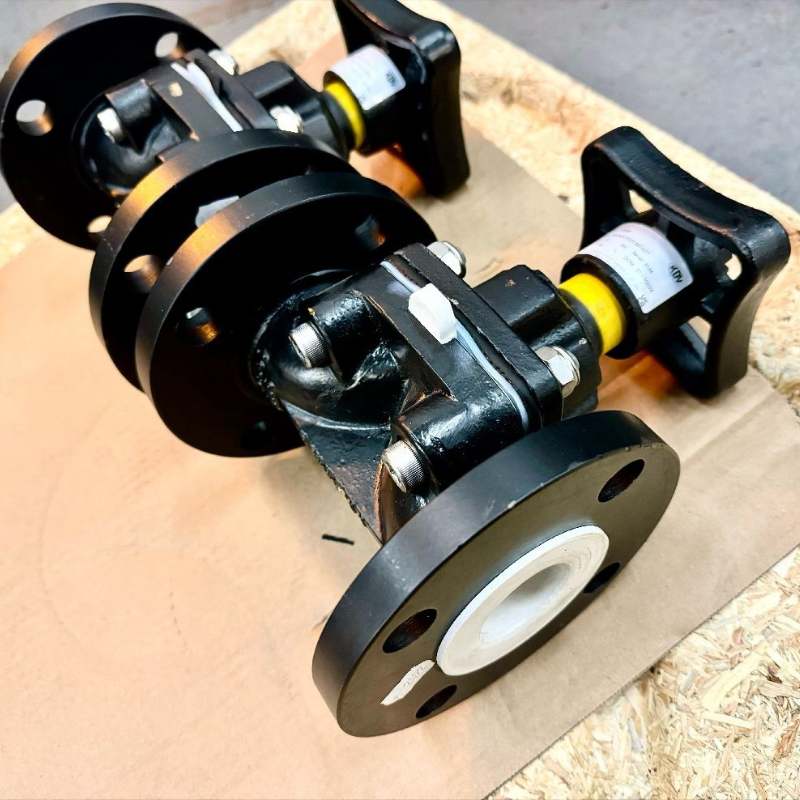

WHY SHOULD YOU USE PLASTIC LINED VALVES?

Exceptional Corrosion Resistance:

The plastic lining (typically made from materials like PTFE, PFA, or PVDF) provides a protective barrier between the valve body and the process fluid. This barrier prevents corrosive substances from contacting the metal parts, significantly extending the valve’s lifespan.

Broad Chemical Compatibility

Plastic-lined valves are suitable for a wide range of chemicals, including strong acids, bases, solvents, and oxidizers. This versatility makes them ideal for industries like chemical processing, pharmaceuticals, and wastewater treatment.

Cost-Effective Alternative to Alloys

Instead of investing in valves made from expensive corrosion-resistant alloys (like Hastelloy or titanium), plastic-lined valves offer similar chemical resistance at a fraction of the cost. This results in significant savings, especially for large-scale applications

Reduced Maintenance and Downtime

The durability of the plastic lining minimizes wear and tear, reducing the frequency of maintenance and replacements. This leads to less operational downtime and lower long-term maintenance costs.

Enhanced Safety

By preventing corrosion-related failures, plastic-lined valves reduce the risk of leaks and spills of hazardous materials. This enhances workplace safety and helps in complying with environmental and safety regulations.

Versatility in Application

Available in various types (such as ball valves, butterfly valves, and plug valves) and sizes, plastic-lined valves can be customized to suit specific application requirements. They can handle a range of temperatures and pressures, making them adaptable to different industrial processes.